Overview of Milk

- Milk is the most valuable protein food that widely consumed by people all over the world. The milk as a raw food is easily available on various dairy farms that are processed to increase the variety of nutrients. Milk provides essential nutrients and is an important source of dietary energy, high-quality proteins and fats. Milk can make a significant contribution to the required nutrient intakes for calcium, magnesium, selenium, riboflavin, vitamin B12 and pantothenic acid. Milk business is very lucrative and it is a high earning job.

- Milk and milk products are nutrient-dense foods and their consumption can add diversity to plant-based diets. Animal milk can play an important role in the diets of children in populations with very low fat intakes and limited access to other animal source foods.

- Milk is a valuable nutritious food that has a short shelf-life and requires careful handling. Milk is highly perishable because it is an excellent medium for the growth of microorganisms – particularly bacterial pathogens – that can cause spoilage and diseases in consumers. Milk processing allows the preservation of milk for days, weeks or months and helps to reduce food-borne illness.

- The usable life of milk can be extended for several days through techniques such as cooling (which is the factor most likely to influence the quality of raw milk) or fermentation. Pasteurization is a heat treatment process that extends the usable life of milk and reduces the numbers of possible pathogenic microorganisms to levels at which they do not represent a significant health hazard.

- Milk can be processed further to convert it into high-value, concentrated and easily transportable dairy products with long shelf-lives, such as butter, cheese and ghee. Dairy products are generally defined as food produced from the milk of mammals. Processing of dairy products gives small-scale dairy producers higher cash incomes than selling raw milk and offers better opportunities to reach regional and urban markets. Milk processing can also help to deal with seasonal fluctuations in milk supply. The transformation of raw milk into processed milk and products can benefit entire communities by generating off-farm jobs in milk collection, transportation, processing and marketing.

What is a Milk Processing Plant?

- Milk is one of the most significant products that are consumed by people from across the world. There are a number of milk processing plants that have been set up in order to cater to the needs of the consumers.

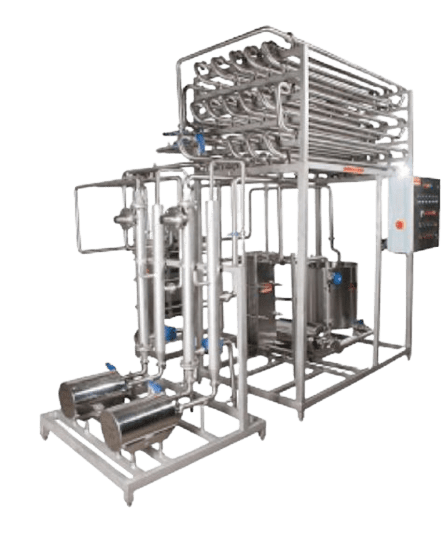

- The milk processing plants include a range of milk processing equipment to perform or handling the various operations of milk like heat treatments, pasteurization, homogenization and some others. The milk plants include the fluid milk production, cheese production, yogurt production, ice cream production to make the huge variety of milk products like cheese, butter, cream, skimmed milk, yogurt, toned milk or double toned milk and much more.

- The milk processing section in processing plants contains all operations of milk like collecting milk from farmers, storing milk in tanks then separating, pasteurizing and homogenizing for making good quality milk products by using some milk processing equipment that is described below.

- Milk Tanks: The milk tanks are the prime components in any milk processing plants that used to store raw milk, skimmed milk or cream. The pre-stack tanks, milk tanks, interim tank and mixing tanks are mainly used in processing plants to provide good quantity milk.

- Pasteurizers: Pasteurization is the process of heat treatment of a product to reduce enzymatic activity and kill pathogenic bacteria. This process can be done by using pasteurizers The main purpose of pasteurization in dairy plants is to make the product safe for use and to extend product shelf life.

- Separators: After pasteurizers, the separators come as third main equipment in milk plants that ensure the excellent products quality and high performance in milk skimming by preventing intake of destructive air.

- Homogenizers: At last, the homogenizer helps to achieve the different variety of products, improves the texture, taste and viscosity of cream or juice-based drink and prevents a cream line and sedimentation in the milk products.

Is Milk Processing Business profitable?

- The demand for milk and milk products is high in all seasons. It is an all-time active market. Milk is a basic necessity in Indian households, and any other product cannot substitute the demand for milk. There is also a huge demand for milk in restaurants, sweet shops, tea shops, and small and big businesses.

- The dairy farm business in India does not require employing skilled labour. Therefore, the labour expenses in this business are comparatively low.

- The milk business involves eco-friendly practices and does not cause harm to the environment. You do not have to spend huge amounts for complying with the environmental laws and regulations.

- The animal waste can be decomposed in the Biogas plants to produce natural gas and can also be used as an organic manure for growing crops and fodder for animals.

- The demand for milk and milk products rises above the normal levels during the time of festivals in India. Therefore, you can make an extra profit when the market is at its peak.

- Animals or livestock are the main factor of this business. You can get insurance for the animals to cover the medical expenses if the animals get infected.

Classification of Dairy Plant

Precisely looking at the basic production features and core operations, dairy plants could be categorized as liquid milk processing plants, products manufacturing plants or combination of these two (Composite Dairy Plants).

a) Liquid milk Processing Plant: In such dairy plant raw milk received at dock, is chilled, processed (pasteurized) and packed for sale. These plants directly procure milk from identified milk sheds or other sources. This type of plant has low value addition but the liquidity of money is very high. The liquidity is better because payment for raw milk is done after 7 or 10 days, whereas realization is either in advance or on the same day. Secondly, the realization money is circulated on daily basis creating an edge for low requirement of working capital.

b) Product Manufacturing Dairy Plants: Raw milk is transformed into value added milk and milk products by employing suitable technologies and using proper equipment. Manufacture of value added products improve the profitability of the overall milk business. Other advantage lies in the conversion of perishable milk into long shelf life products. This aspect has high impact due to perishable and seasonal nature of milk production. Long shelf life products are also suitable for distant marketing.

c) Composite Dairy Plant: Most of the dairy plants do have facilities for processing and packing of liquid milk and milk products. In this way, dairy plant can be benefited for high liquidity along with the advantage of increased shelf life and value addition. Such milk plants are more viable and sustainable.

Planning Considerations for Dairy Plant

Planning for dairy plant should consider following aspects:

a) Forecasting for milk business with regards to milk procurement and marketing;

b) Market analysis for product demand;

c) Availability & requirement of land, topography to suit disposal of waste and communication;

d) Analysis for requirement and availability of water; and

e) No objection from municipal, pollution and aviation authorities.

Depending upon the status of above-mentioned factors, dairy plant of desired capacity could be designed for processing and production of selected products. Accordingly full consideration is to be given for selection of plant location, design and layout.

What is a Mini Dairy Plant?

- It is a small set of equipment in batch or continuous configuration, which could be installed at the dairy farm itself for improving the value addition capacity of a dairy farm and making it commercially more viable and thus sustainable.

- It also helps in making farmers move ahead by creating forward integration linkages with the end consumer.

- Mini dairy plants are small milk factories specially produced for producers who want to produce dairy products with low capacity.

- Large areas are not required to set up Mini dairy plant. These facilities are usually installed in dairy farms, restaurants, hotels and organic markets.

- You can also install Mini dairy plant in containers and take them to the desired location.

- Mini dairy plant can also consist of a single tank, and several interconnected machines.

- The machines are practical and easy to use and there is no need to use steam in Mini dairy plant. Tanks and machines can run on electricity.

- The cost of production in the mini dairy plants will be cheaper because of low cost of raw material, cheaper manpower and other production related aspects.

Eight steps to follow to start a profitable Milk Processing Business

1. Create a Business Plan

- Entrepreneurs should focus on the business plan at first before executing it. The plan layout helps prepare the company for any unpredictable events and prepares them to accomplish their targets less time and significantly less investment.

- However, it is the need of the hour to emphasize the plan before setting your business because any small twist and turn can lead your business to uncountable losses and the deterioration of the customers’ health.

- The efficiency and production of milk processing depend upon the plan concerning the milk processing business in India. Negligence, by any means, can prove to be a disaster for the business entrepreneurs. Hence, starting from essential permits and licenses and registration of the milk processing business in India, every small detail should be given. Business plans often act as a security valve for enterprises.

2. Name your Milk Processing Business

- Select a name that people can relate to your Milk processing company. Do not forget to check the availability of a similar domain name to the company name. This helps you in creating a website similar to the company name.

3. Choose a Location for Milk Processing Factory

- The milk processing business in India requires ample space for buildings, future business expansion, parking lot, empty cans, a manufacturing company, packaging unit, etc. About two acres of land is appropriate for milk processing.

- However, the plant’s location must be closer to the milk-producing area in a product manufacturing unit. The site’s background should have proximity to all the required facilities like road/rail facilities, services, water, electricity, raw materials, social infrastructure, etc.

- Proper drainage maintenance is a must. The unit can either be an owned one or taken on rent. Apart from all this, special care is needed regarding its workers’ safety and working in a secure area. The building should be well equipped with all the necessary precautions to avoid any mis- happening.

4. Make the Business Legally Compliant

Registration of the milk processing business with the registrar of firms or ROC is a must depending upon the type/form of business you choose. You can either get it registered as a sole proprietorship or any other form of the company depending upon the business organization’s capital infused and budget. You can also choose the appropriate name for the manufacturing unit and can get it registered in that name.

Permits & Licenses–

- NOC from the fire department

- GST registration

- MSME registration

- Trade License

- FSSAI food license

- BIS standards

- Special permission from PCB

- MMPO registration with the Commissioner, Dairy Development, concerned state, or the authority.

- Insurance policy

- License from Factory inspector for installation of the boiler

5. Machine & Equipment for Milk Processing

The Milk Production Plant basically comprises of:

- Milk Reception Section

- Storage Tank for chilling of raw material before process

- Plate Type Pasteurizing Section / Cream separation/ Homogenizing Section

- Utility Section( Hot water Generator, Refrigeration System)

- Storage of processed milk in storage tank

- Packaging Section (Pouch, Bottle Packing)

6. Cost (investment) of start Milk Processing Plant

The cost of Milk Processing Plant depends on the capacity of Milk, the business owner wants to process and the milk availability on per day basis. The approximate price of a small scale set up starts from 4 lakhs onwards and it can go up to 15-18 lakhs for a medium or large scale set up.

7. Milk Production Process

The milk manufacturing process can be summarized as follows:

- Collecting – Raw milk is collected and cooled at a particular temperature to make it ready for further processing.

- Separating – Any kind of sediment or debris is removed from milk in this step. A separator separates lighter milk and heavier milk fat to give cream and skim milk.

- Pasteurizing – The extracted milk is heated to a certain temperature for killing off the pathogenic microorganisms present in it. It also increases the time for which you can store the milk in a tank.

- Homogenizing – Homogenizing, as the name suggests, is the process to make milk even throughout. It is done by breaking down the heavier particles present in milk.

- Storage – The milk is then stored in a storage tank for further delivery either to the plants or the manufacturers of dairy products. This is the last step in the process of milk production.

Milk plants can be small, medium or big depending on the investment made by the owner. There are number of dairy products like ghee, cream, butter, toned milk, double toned milk and skimmed milk that are also manufactured in milk plant. Milk is initially dumped in big milk tank from the milk tankers after that it chilled in a chilling unit. This chilled milk is pasteurized in the milk pasteurizer and cream is divided from the cream separator which gets skimmed milk. Milk is generally categorized as toned milk, skimmed milk, double toned milk or full cream milk.

8. Promote your Products

There is an immense number of ways by which you may sell your milk processed products. You may choose to put it on an e-commerce website or sell it directly in the stores. However, in the current scenario, most of these entrepreneurs are opting for online portals for selling their products like Grofers, BigBasket, Amazon pantry, milk basket, etc. Listing your products in these portals is an efficient way to sell your products.

You may also choose to sell it directly to dairy booths, stores, agencies, etc. Apart from this, you may also put your products on your website.

FSSAI Role in Milk Processing Business in India

- The food control safety measure is required to bridge the gap between safe food and adulterated food. The food industry needs more flexible standards and efficient in producing and marketing food, thus ultimately serving the consumers with a protective sheet. FSSAI’s role in food quality is essential for smooth functioning.

- Maintaining the food quality standards to ensure safety and satisfaction to every consumer is every Food/beverage business entrepreneur’s aim. India’s food safety and standards authority (FSSAI Registration) play a significant role in controlling and maintaining the safety procedures. FSSAI ensures that all the safety standards complied before floating the milk products out for sale.

Financial Assistance

- Financing to food processing/milk processing falls under priority sector lending. The loans to these units meeting the criteria of MSME are classified under the MSME sector. Milk processing units can be financed by any scheduled commercial banks, Regional Rural Banks, and Cooperative Banks.

- Important terms and conditions of financing need to be discussed in detail while borrowing money from these institutions. The promoters of these units can approach any financing bank for finance.

- It is mandatory to take a bank loan to avail of various schemes/regulations of government. Therefore, the entrepreneurs who are desirous of availing subsidy should also adhere to the means of finance, which is the quantum of bank loan & margin under the specific scheme. Apart from taking loans, there are other ways to arrange for finances like crowdfunding, angel investor, etc.

Explore

Related Products