Navigating the Liquid Filling Machine: An exhaustive guide on selecting the right one for your business.

Filling machine remains crucial in the dynamic world of manufacturing and packaging as it determines product integrity, efficiency, and profitability. Selecting the right liquid filling machine for your particular products can be very challenging due to the many choices available.* As such, this extensive guide will give you all the information you need for your business decision in order to be well prepared.

.

Understanding Your Products and Production Requirements

Before delving into the technical aspects of filling machines, it’s crucial to thoroughly understand the characteristics of your products and the demands of your production process. This includes factors such as:

-

Product viscosity: Liquids with different viscosities require different filling mechanisms. For instance, thin liquids like water can be handled by gravity fillers, while viscous liquids like honey or sauces may require piston or pump fillers.

-

Container type: The shape, size, and material of your containers play a significant role in determining the compatibility with the filling machine. Rigid containers like bottles or jars may be suitable for gravity or piston fillers, while flexible pouches may require volumetric fillers.

-

Production volume: Accurately assess your current and projected production needs to select a machine with the appropriate capacity. Low-volume production may call for manual or semi-automatic fillers, while high-volume operations may necessitate fully automatic machines.

-

Fill accuracy requirements: If your products require precise filling volumes, ensure the machine offers high accuracy and consistency. This is particularly important for products sold by volume or for those with sensitive applications.

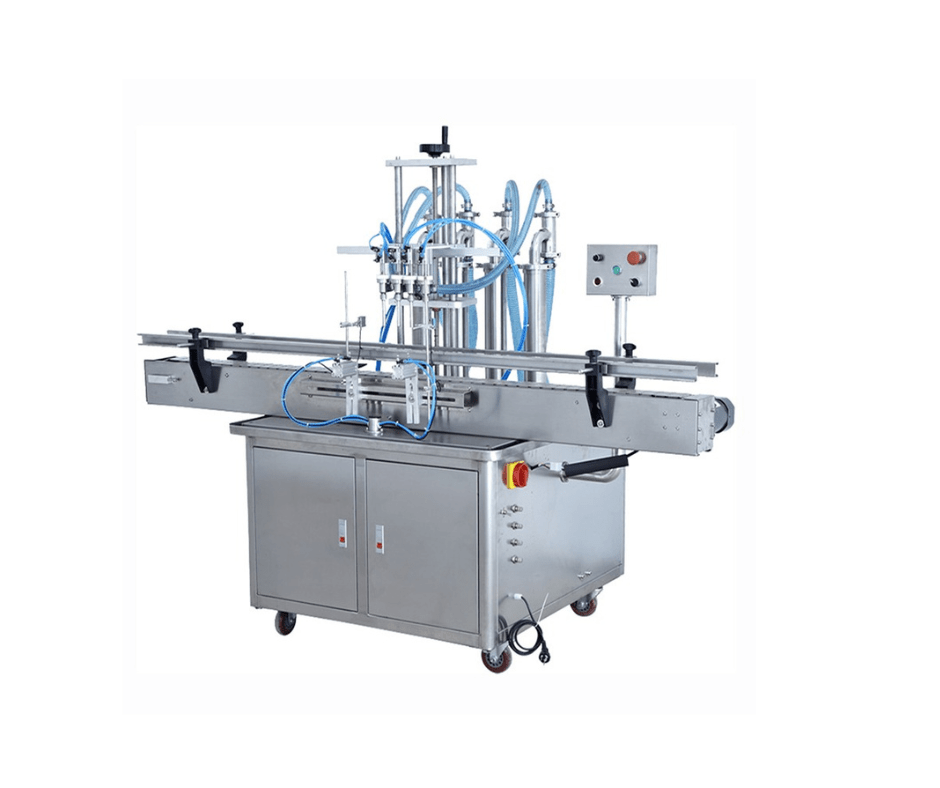

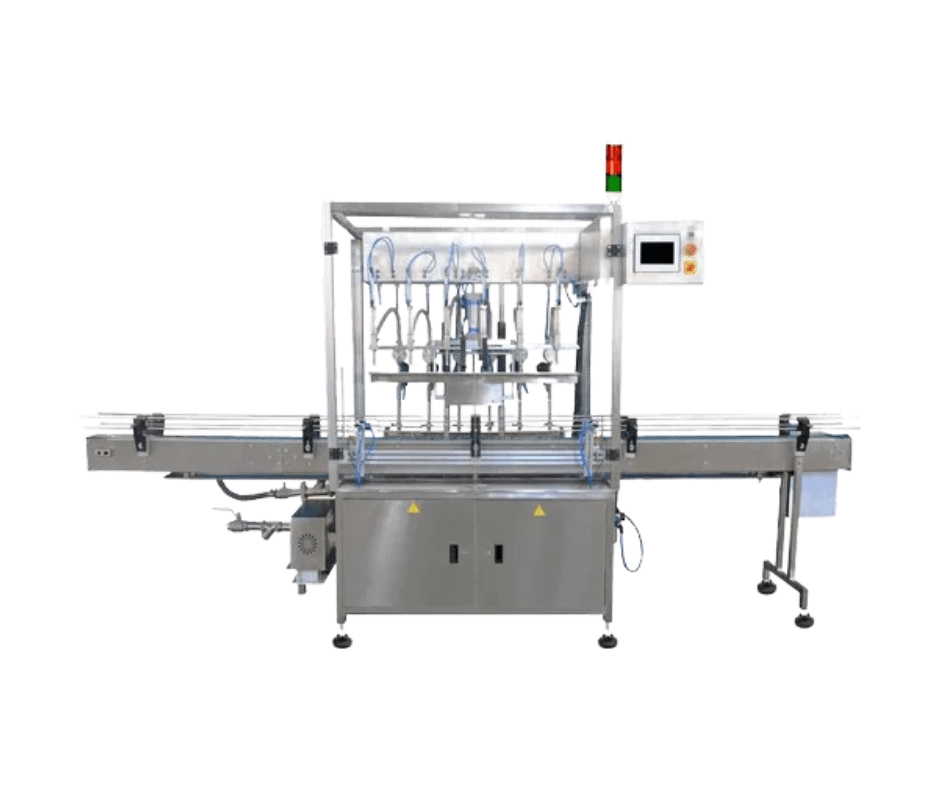

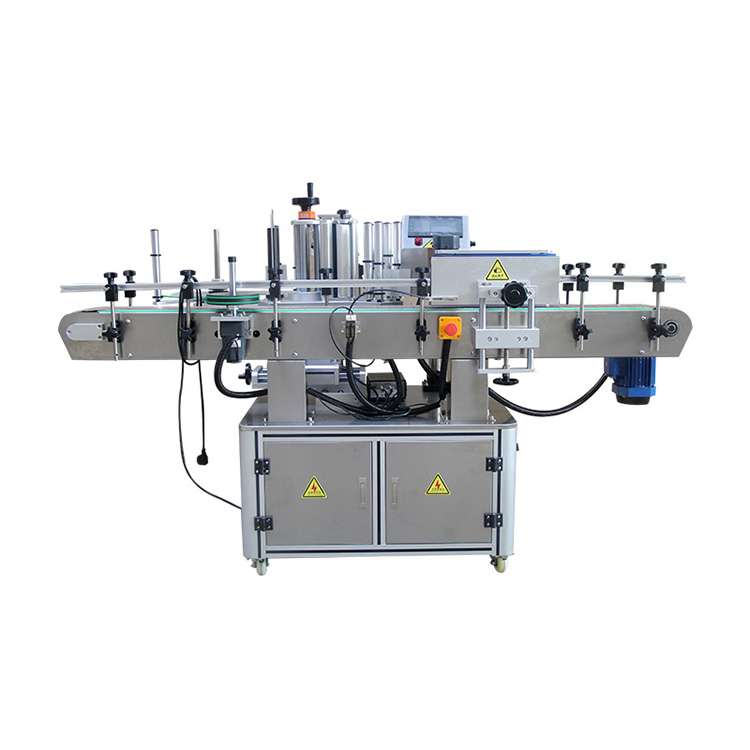

Exploring the Liquid Filling Machine Spectrum

Liquid filling machines come in a diverse array of designs, each tailored to specific product applications. Here’s a brief overview of the common types:

-

Gravity filling machines: Ideal for free-flowing liquids with low viscosity, these machines utilize gravity to dispense product into containers.

-

Volumetric filling machines: Employing pistons or pumps, these machines deliver precise volumes of product, making them suitable for viscous liquids and pastes.

-

Net weight filling machines: Utilizing load cells, these machines ensure accurate filling based on weight, particularly useful for high-value products or those with strict weight tolerances.

-

Vacuum filling machines: Suitable for filling containers under a vacuum, these machines are ideal for products sensitive to air exposure, such as beverages or food items.

Considering Additional Factors

Beyond product and production considerations, there are other crucial factors to evaluate when choosing a liquid filling machine:

-

Ease of cleaning and maintenance: Regular cleaning and maintenance are essential for optimal machine performance and product quality. Ensure the machine is designed for easy access and cleaning, and that replacement parts are readily available.

-

Automation level: Decide whether a manual, semi-automatic, or fully automatic machine aligns with your production scale and labor availability. Manual machines require more operator involvement, while fully automatic machines minimize human intervention but may have higher upfront costs.

-

Integration with existing packaging lines: Ensure the filling machine seamlessly integrates with your existing packaging equipment to maintain a smooth workflow. Consider compatibility with conveyor systems, labeling machines, and capping equipment.

-

Budget and return on investment (ROI): Balance upfront costs with long-term profitability to select a machine that delivers a positive ROI. Evaluate factors such as initial purchase price, maintenance costs, labor savings, and potential increase in production efficiency.

Seeking Expert Guidance

Choosing the right liquid filling machine is a significant investment that impacts your product quality, production efficiency, and overall business success. Consulting with experienced industry professionals can provide invaluable insights and guidance throughout the selection process. They can assess your unique requirements, recommend suitable machine options, and help you navigate the technical complexities involved.

Explore

Related Products