Mini Ice Cream Plant

Overview

Mini Ice Cream Plant

TechQu offers mini ice cream users end-to-end services to allow the mini plants with an emphasis on start-ups, small producers, and even companies intending to venture into the frozen dessert market. We have mini ice cream plants that ensure the use of the best technology and minimal/compact and efficient design, thus fitting perfectly in the production of quality ice cream, gelato, and frozen desserts on a smaller scale yet meeting international hygiene/consistency standards.

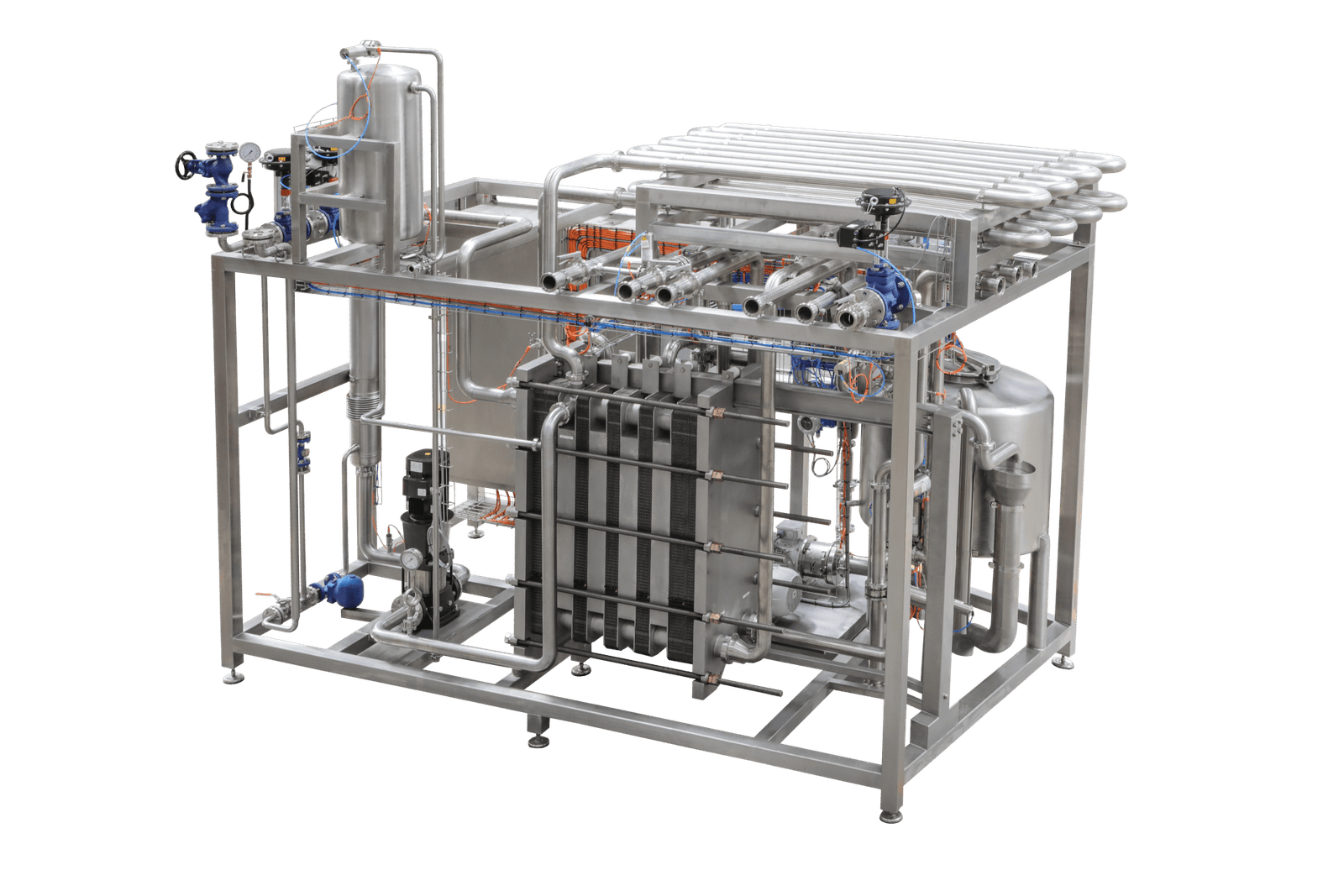

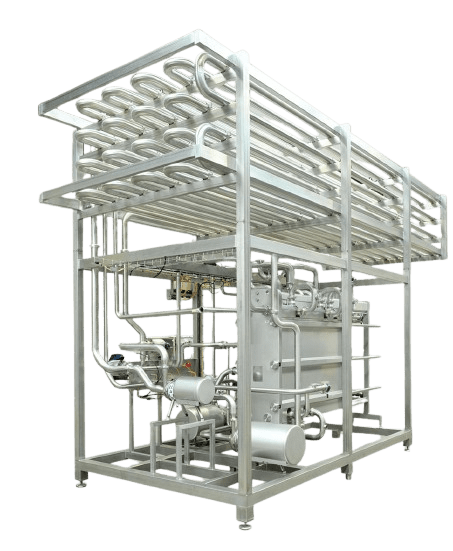

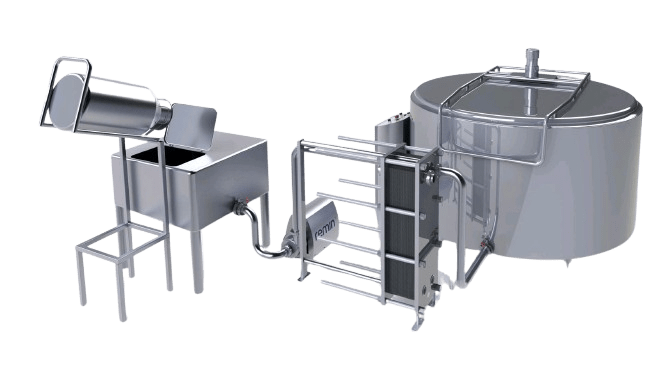

A mini ice cream plant is designed to undertake the entire process of production that includes mix preparation, pasteurization, homogenization, aging to freezing, flavor addition, and packaging. The different stages are meant to maintain a smooth process and the taste, the texture, and the creaminess of the final product. The plant The plant allows a flexibility of experimenting on the recipes and tastes of different tastes and gives the manufacturers freedom to meet various customer tastes and markets.

Comprising high-grade stainless steel and food-grade materials, the plant is lasting, clean, and minor to maintain. Clean-in-place systems are contamination-free, and PLC-based automation and convenient-to-use controls provide accuracy and efficiency during production. At such a small scale, the plant ensures the quality that is of a consistent nature; hence, it is applicable to retail and specialty outlets.

The mini ice cream plants of TechQu are small and economical, with space and resources easily utilized. They suit the firms that aim to go small and increase the production capacity when the demand increases. The conservation of energy makes such plants a good investment for upcoming brands due to the cost-saving features.

TechQu offers complete customization of the turnkey solution, including concept development and plant design, fabrication of equipment, installation, training, and after-sales services. All of the plants are designed to respond to the goals and aim of the production, product line-up, and the strategy of the market, making them flexible and able to grow enormously with time. Sweet cup, cone, and tub packaging solutions can be easily integrated in bulk packaging to meet market-expected requirements.

- Milk Reception Section

- Storage Chilling Raw Material before Processing

- Plate-Type Pasteurising Section / Cream separation / Homogenising

- Utility Section (Hot water Generator, Refrigeration System)

- Storage of processed milk in a storage tank.

- Packaging Section (Pouch, Bottle Packing)

Explore

Related Products