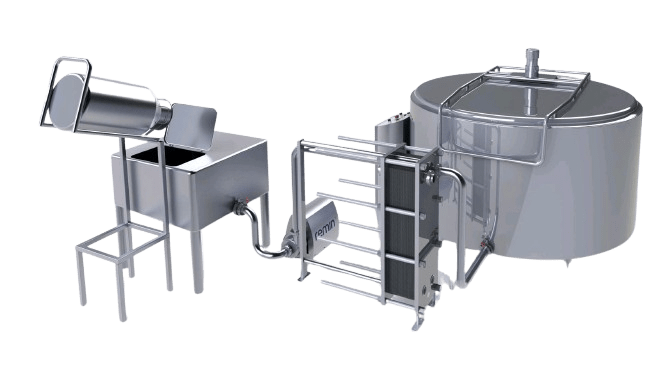

- Milk Reception Section

- Storage Chilling Raw Material before Process

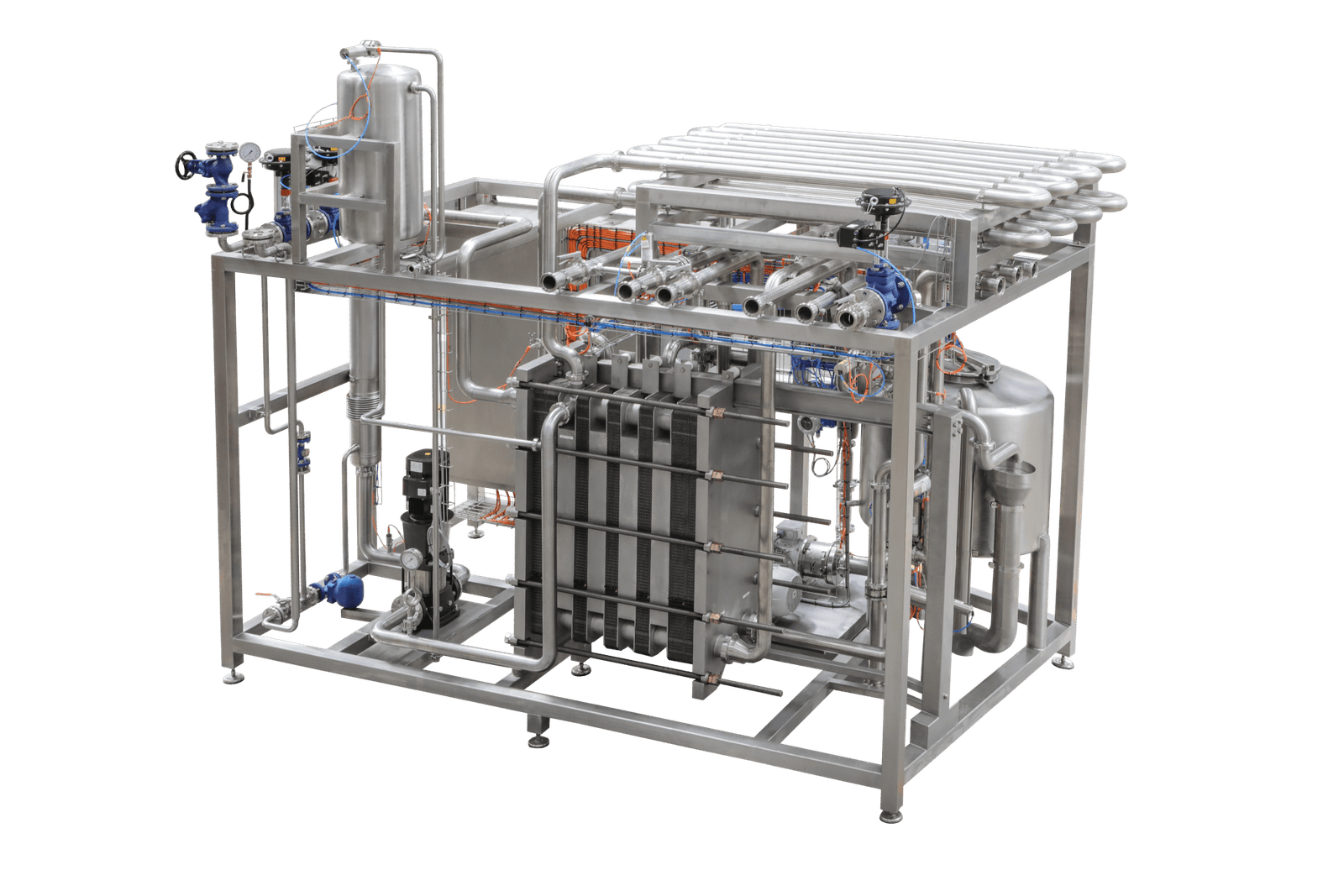

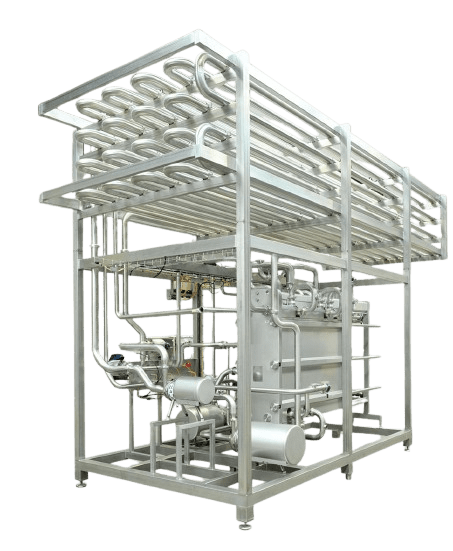

- Plate Type Pasteurising Section / Cream separation/ Homogenising

- Utility Section( Hot water Generator, Refrigeration System)

- Storage of processed milk in storage tank.

- Packaging Section (Pouch, Bottle Packing)

Mini Beverage Plant

Overview

Mini Beverage Plant

TechQu offers complete systems of mini beverage plants, which are aimed at helping startups, small-scale manufacturers, and developing and expanding enterprises in the beverage sector. Our mini beverage plants are small, efficient, and multifunctional, thus suitable for making many types of beverages, including fruit juices, flavored water, soft drinks, energy drinks, dairy-based beverages, and health drinks. These plants embraced sophisticated technology and a flexible design, which enables the manufacturers to produce quality products with minimal space and cost.

The mini beverage plant is designed to address the total process chain, which includes raw material preparation and the mixing process, as well as the pasteurization, filling, and packaging process. Be it carbonation of soft beverages, homogenization of milk-based beverages, or dosage and mixing of flavors, TechQu solutions assure a smooth, controlled process.

PLC-based automation and easy-to-use controls offer precision, efficiency, and flexibility even in small-scale production. They include clean-in-place systems and sterilize-in-place systems to ensure the safety of products with minimum downtime and minimum manual handling.

The most important strengths of the TechQu mini beverage plant are its scalability and adaptability. Small businesses and entrepreneurs can start with less capacity and will grow with higher demand, without losing quality.

TechQu can provide full turnkey solutions, including concept development, plant layout, equipment fabrication, installation, training, and after-sales services.

Explore

Related Products