Mini Flavor Milk Plant

Overview

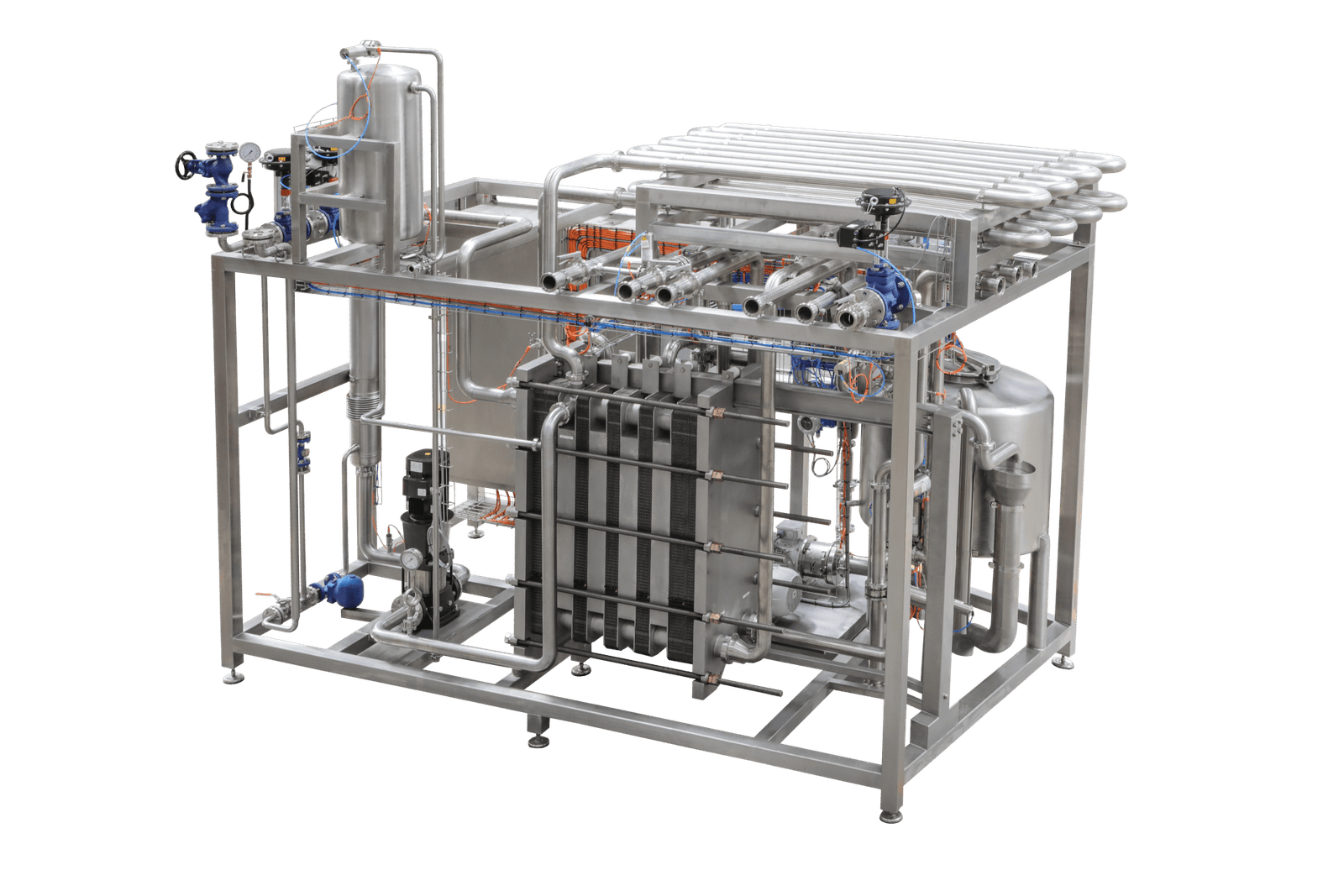

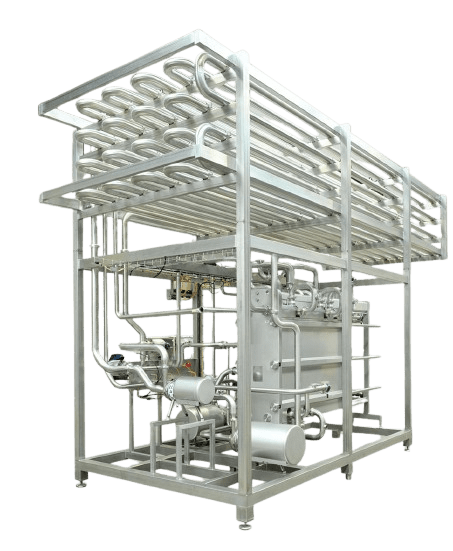

Mini Flavour MIilk Plant

Mini Flavour MIilk Plant

The plant was made of high-grade stainless steel and food-grade products to ensure the high international hygiene and safety standards. Integrated clean-in-place systems ensure smooth operation and minimize downtime, and PLC-based automation coupled with easy controls provides accuracy, efficiency, and ease of operation. The plant with a compact design guarantees high performance; hence, it is suitable to meet both niche and local market needs.

The mini flavored milk plants by TechQu are cost-effective and can be scaled, meaning that the small-scale producers can produce small amounts and expand with an increase in demand. They are energy efficient and space saving and hence the best option for any entrepreneur and any growing dairy that has plans on adding value-added products to its portfolio.

KEY SECTION

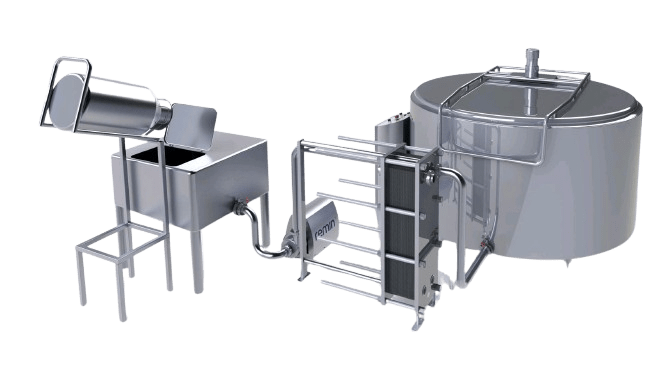

A milk processing plant is a facility where milk is received, processed, and packaged for distribution and consumption. The process typically includes several steps, such as

- Milk reception: Milk is received, tested for quality and temperature, and stored in a holding tank.

- Standardization: The milk is standardized to adjust the fat content to a specific level.

- Filtration: The milk is filtered to remove any impurities.

- Pasteurization: The milk is heated to kill any bacteria and extend its shelf life.

- Homogenization: The milk is homogenized to evenly distribute the fat particles and prevent cream separation.

-

Packaging: The milk is packaged in bottles, cartons, or bags and stored in a cool, dry place until it is ready to be shipped to customers.

The Milk Production Plant’s key feature:

- High-grade stainless steel construction

- Automation and control systems

- Energy efficiency

- Easy operation/integration

Explore

Related Products