Mini/Pilot Milk Processing Plant

Overview

Mini/ Pilot Milk Processing Plant

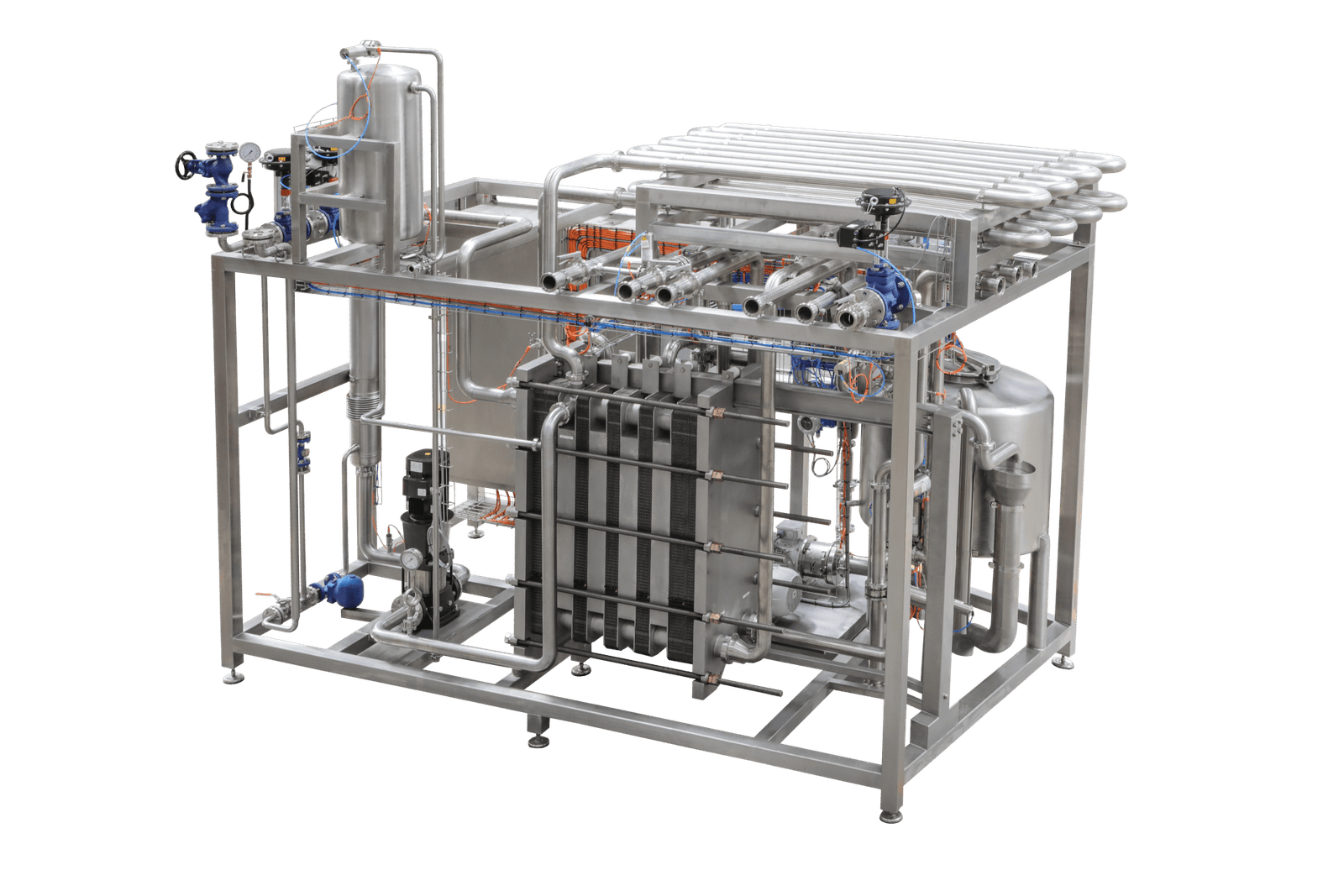

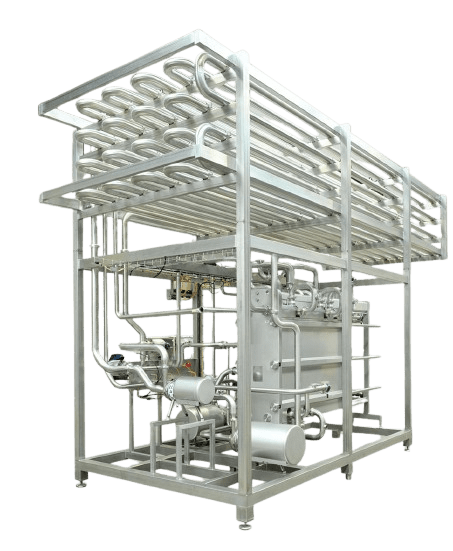

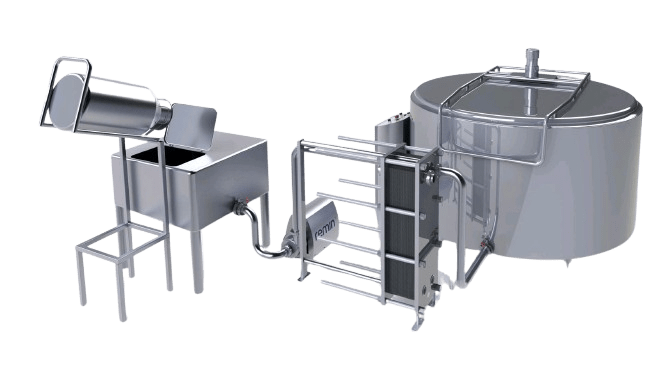

TechQu offers complete solutions to mini/pilot milk processing plants designed to serve startups, research institutions and training centers, and small-scale dairy producers. Our plants bring together compact design and a high level of technology that will help us process milk efficiently into a variety of products, including pasteurized milk, flavored milk, curd, yogurt, paneer, butter, and ghee. These plants have been constructed with a high level of accuracy and deviation, which are very suitable in pilot production and in restricted commercial-scale production.

The mini/pilot milk processing plant also encompasses all processes undertaken in the production of dairy products, beginning with the milk reception and chilling, followed by filtration, pasteurization, homogenization, separation, and eventual beverage packaging. Each processing is designed so that it does not alter the nutritional content and/or is fresh from milk, coupled with hygienic and safe processing. It is also possible to customize the plant to cater to several product lines to allow producers the flexibility to experiment with recipes or increase their portfolio without massive investments.

The plant is made of high-grade stainless steel and food-grade materials and is assured of its ability to meet the international standards of hygiene and safety in relation to dairy. Combining a clean-in-place system and sterilize-in-place to ensure continuous operations with a minimum number of people handling it further minimizes contamination challenges and downtime. Automating through PLC vs. handling manually offers accuracy and consistency due to its robust, user-friendly controls that provide quality uniformity in each batch.

The mini/pilot milk processing plants of TechQu are miniature, energy efficient, and cost-effective, hence suitable for businesses and institutions that have minimal space and resources. They are expandable to meet the additional demands of the production as the needs increase, giving the customer a smooth transition between pilot-scale production and commercial production.

TechQu offers fully tailored turnkey solutions, featuring concept design and plant layout, fabrication, training, and after-sales service provision. The plants are customized to the needs of the client, product mix, and its operations, which guarantees the creation of an optimal blend of flexibility and productivity.

- Milk Reception Section

- Storage Chilling Raw Material before Processing

- Plate-Type Pasteurising Section / Cream separation / Homogenising

- Utility Section (Hot water Generator, Refrigeration System)

- Storage of processed milk in a storage tank.

- Packaging Section (Pouch, Bottle Packing)

Explore

Related Products