Multi Milk Products Plant

Overview

Multi Milk Products Plant

TechQu offers the Multi Milk Products Plant a full end-to-end solution that will allow effective milk processing and diversification of value-added products. We possess the knowledge of all the processes involved, including raw milk treatment, including pasteurization, and the manufacture of milk products, including paneer, curd, ghee, flavored milk, and other dairy products.

Through innovative technologies and tailor-made plant design, we assist dairies to get high-quality production, increased shelf life of goods, and efficiency of the operations. We design our solutions to support small- and large-scale requirements, which are scalable and flexible.

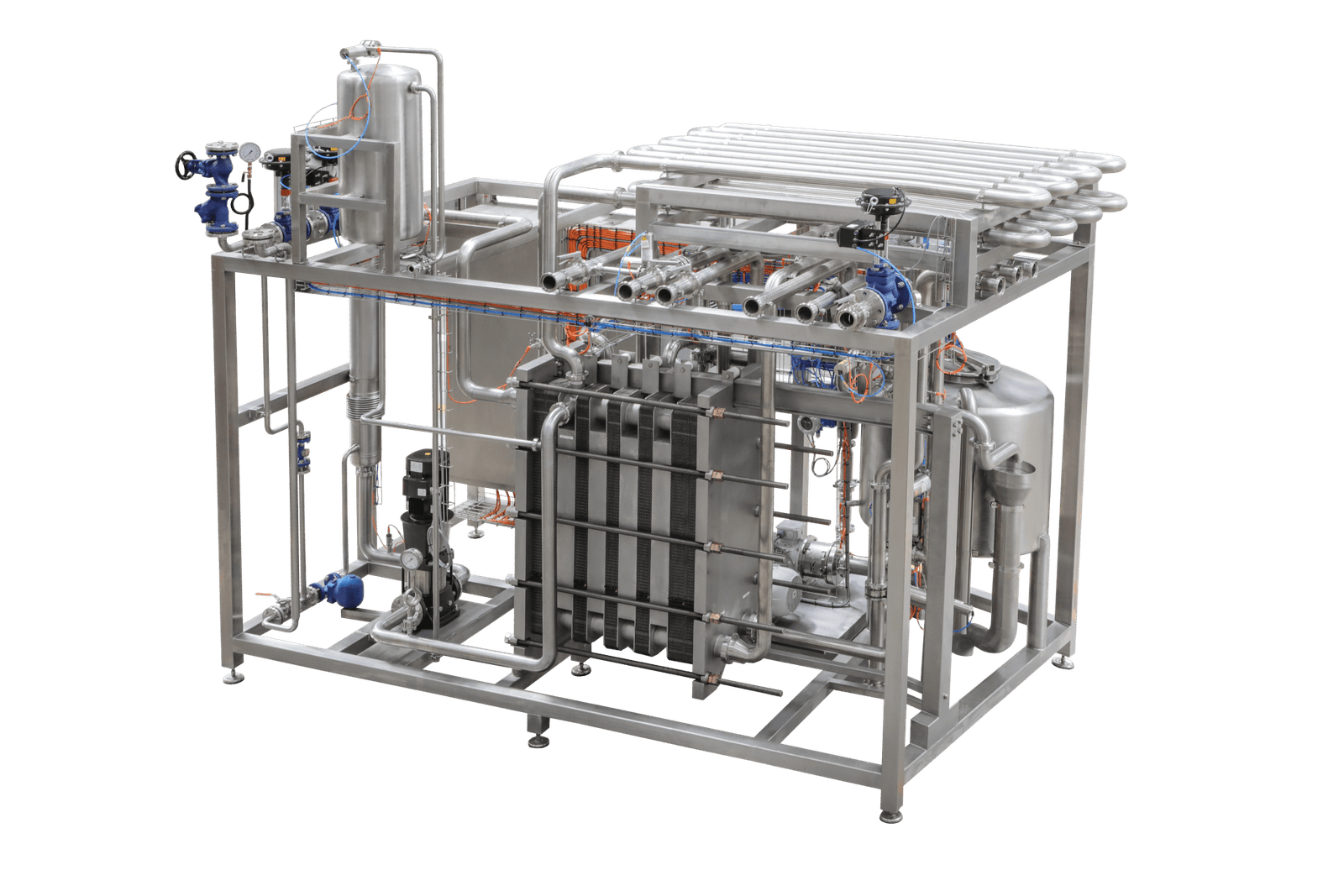

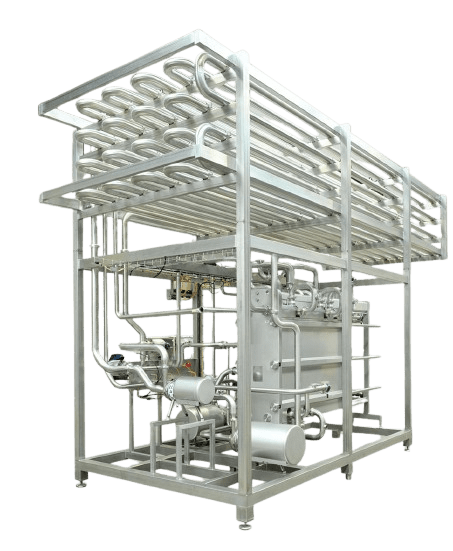

The use TechQu makes of multi-milk products is the designing of the plants using high-grade stainless steel, with consideration being paid to sanitation and durability. Advanced automation and PLC-based and monitoring systems are provided in each plant to ensure traceability, hygiene, and consistency throughout the entire production line. Clean-in-place and sterilize-in-place systems are combined to guarantee contamination-free processing, and energy-beneficial systems lead to a reduction in the cost of operations and the impact on the environment.

Our multi-milk product plants are configured to the needs of the clients, like capacity, product mix, and market needs. Regardless of whether it manufactures consumer-packaged dairy items and beverages or value-added dairy products to be packaged and driven to retail sales and foodservice establishments, TechQu provides every factory with a functioning milieu that guarantees a smooth operation and high productivity and is delivered with easy scaled access. Bottles, pouches, cups, and/or bulk You can also have packaging solutions tailored to bottles, pouches, cups, or bulk solutions depending on the customer requirements.

TechQu provides comprehensive, complete, turnkey solutions encompassing the concept design and thorough engineering through manufacture, installation, commissioning, training, and after-sales services. As a company experienced in the dairy-processing industry, we know how multi-product operations can be very complicated and thus offer inventive systems that are flexible, efficient, and offer quality assurance.

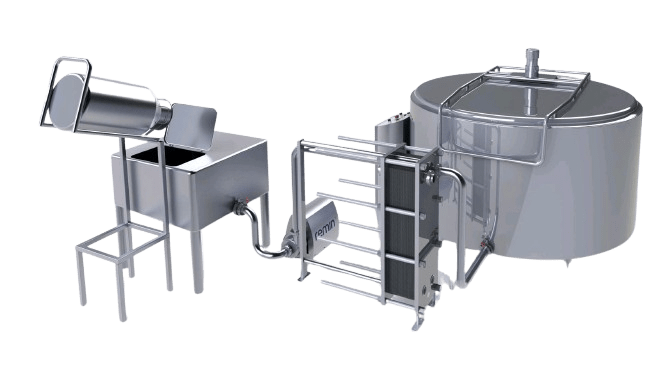

- Milk Reception Section

- Storage Chilling Raw Material before Process

- Plate Type Pasteurising Section / Cream separation/ Homogenising

- Utility Section( Hot water Generator, Refrigeration System)

- Storage of processed milk in storage tank.

- Packaging Section (Pouch, Bottle Packing)

Explore

Related Products