Cheese Production Process – Complete Turnkey Solutions by TechQu

What is Cheese?

Cheese is a nutritious, protein-rich dairy product made by curdling milk using enzymes and bacterial cultures. It is widely consumed across the globe in various forms such as Paneer, Cheddar, Mozzarella, and processed cheese. Cheese offers a longer shelf life, high versatility, and great commercial value—making it a profitable dairy product for food processors and entrepreneurs alike.

TechQu – Your Partner in Cheese Manufacturing Solutions

TechQu Engineering provides end-to-end turnkey solutions for setting up fully-automated and hygienic Cheese Production Plants, tailored to your scale and budget. From plant design to installation and after-sales support, we ensure smooth, compliant, and cost-effective operations.

Step-by-Step Cheese Production Process :-

Here’s how the cheese production process works:

-

Milk Reception & Pre-Processing

-

Fresh milk is received, filtered, and chilled

-

Standardization of fat and solids

-

Pasteurization to kill pathogens

-

-

Addition of Starter Culture & Coagulants

-

Lactic acid bacteria are added

-

Rennet or acid used for curdling

-

-

Curd Formation & Cutting

-

Curd is formed and cut into cubes

-

Helps release whey

-

-

Cooking & Stirring

-

Curd is heated and stirred to firm up texture

-

Target temperature depends on cheese type

-

-

Whey Draining

-

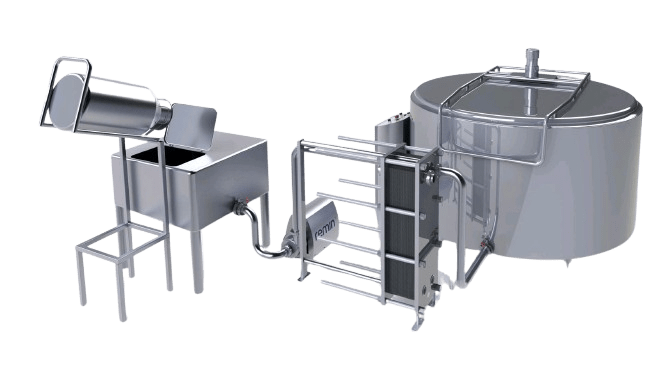

Whey is separated from the curd using draining equipment

-

-

Cheddaring or Kneading (for certain types)

-

Curd is stacked, flipped, and allowed to mat

-

Moisture is reduced and acidity increases

-

-

Milling & Salting

-

Curd is chopped and salt is added for flavor & preservation

-

-

Molding & Pressing

-

Cheese is shaped into blocks or wheels

-

Pressed to remove excess whey and shape the product

-

-

Packaging & Aging

-

Fresh cheese is vacuum-packed or wrapped

-

Some cheese types are aged in temperature-controlled rooms

-

TechQu’s End-to-End Cheese Plant Solutions Include:

-

Plant Design & Layout Optimization

-

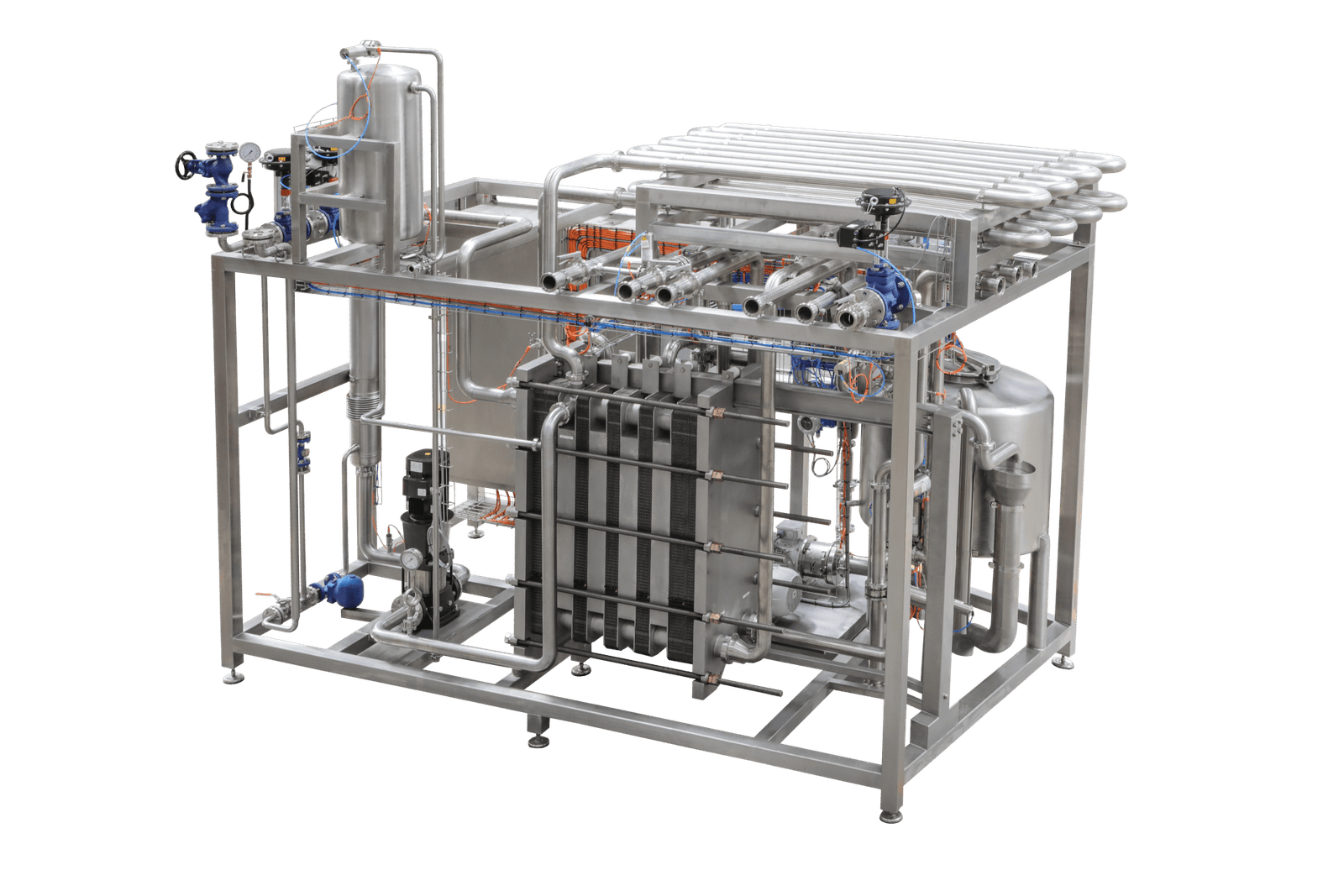

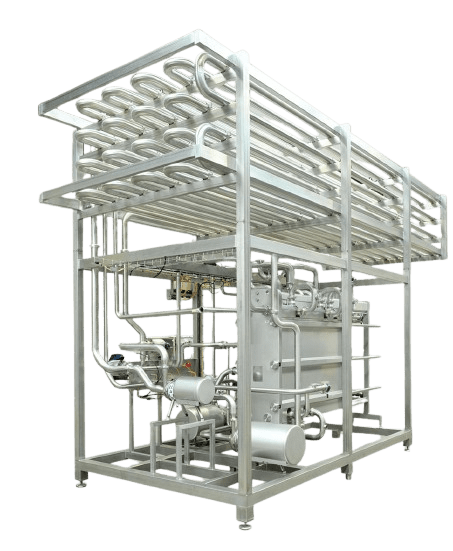

Custom Fabrication of Cheese Equipment

-

Automation & Control Systems

-

In-line Quality Monitoring & CIP Systems

-

Packaging, Storage, and Logistics Setup

-

Compliance with Global Food Safety Standards

Why Choose TechQu?

- 10+ Years of Engineering Experience

- Trusted by Dairy Brands Across India & Overseas

- Turnkey Project Execution from Concept to Commissioning

- Tailored for Small, Medium & Large-Scale Cheese Plants

📞 Get in Touch!

Seeking to start a company for making paneer?

TechQu Engineering is your trusted partner for complete dairy processing solutions.

📞 Call Now: +91 89360 15188

🌐 Visit: www.techqu.co.in

📧 Email: projects@techqu.co.in

👉 Start your dairy journey with TechQu — from design to commissioning!

Explore

Related Products