Curd Production Process – End-to-End Solutions by TechQu

What is Curd?

Curd, also known as dahi, is a traditional dairy product formed by the natural fermentation of milk using lactic acid bacteria. It is a rich source of probiotics, calcium, and protein, and is widely consumed across households, restaurants, and the food processing industry. With increasing health awareness and demand for ready-to-eat dairy products, curd manufacturing is now a profitable and scalable business opportunity.

TechQu’s End-to-End Curd Production Plant Solutions

TechQu Engineering offers complete turnkey solutions for setting up fully automated, hygienic, and high-capacity curd manufacturing plants. Whether you’re planning a small-scale setup or a large commercial dairy unit, we handle the entire project lifecycle—from design to installation and maintenance.

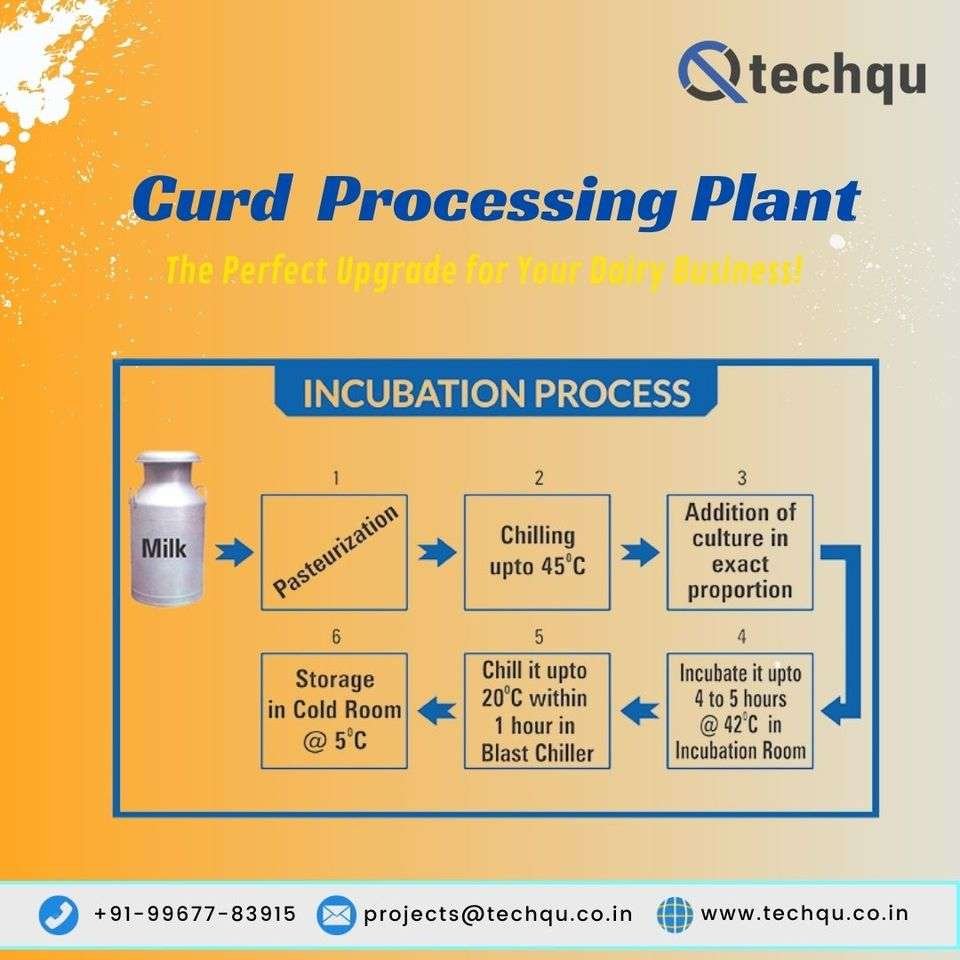

Step-by-Step Curd Production Process :-

-

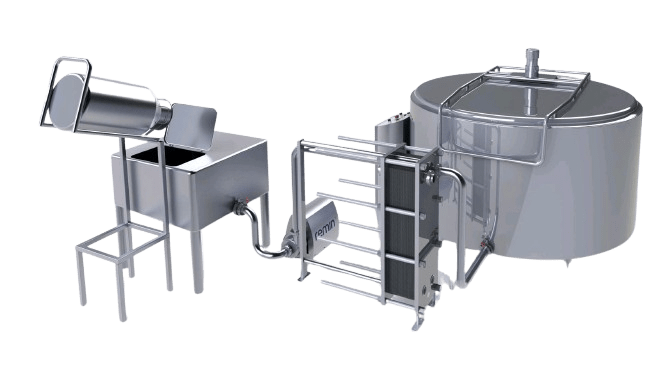

Milk Reception & Pre-Treatment

-

Raw milk is collected, filtered, and chilled

-

Pre-treatment includes clarification and standardization of fat content

-

-

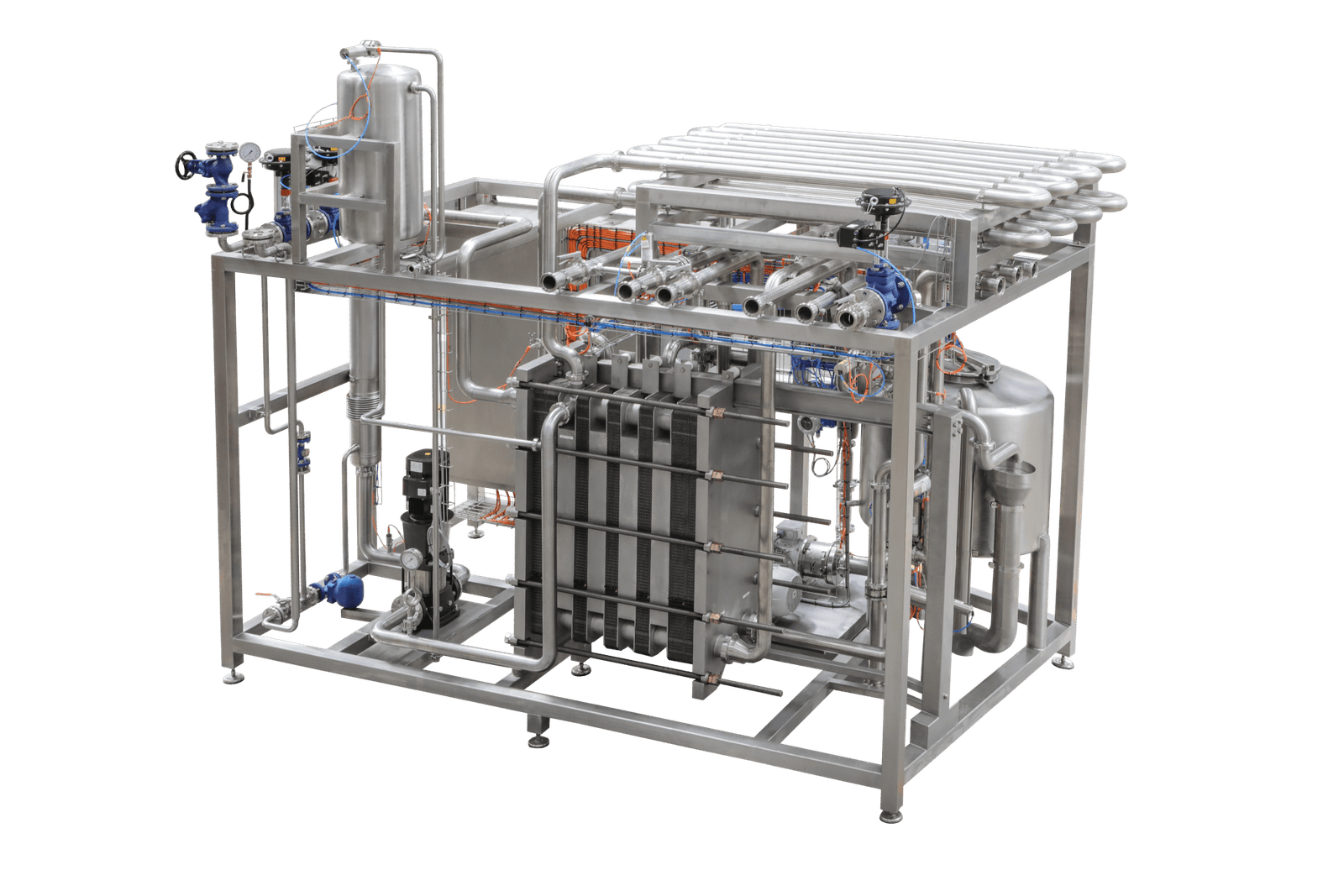

Pasteurization

-

Milk is pasteurized at high temperatures to kill harmful bacteria

-

Ensures long shelf-life and safe fermentation

-

-

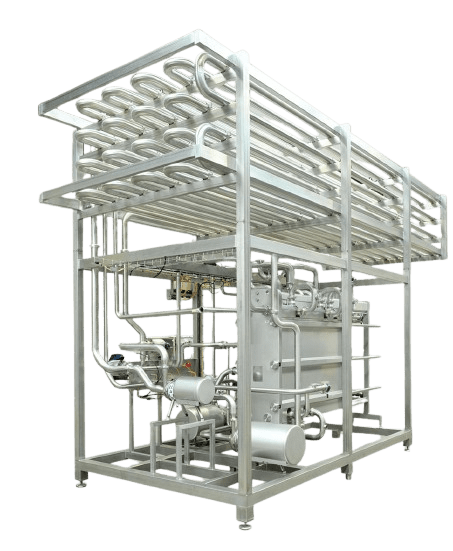

Homogenization

-

Ensures uniform texture and consistency

-

Prevents cream separation

-

-

Cooling & Inoculation

-

Pasteurized milk is cooled to fermentation temperature

-

Starter culture (lactic acid bacteria) is added to initiate curd formation

-

-

Incubation

-

Milk is held at a controlled temperature (40–45°C) for a set period

-

Fermentation converts lactose to lactic acid, forming curd

-

-

Cooling & Packaging

-

Once set, curd is cooled to stop fermentation

-

Filled into cups, pouches, or bulk containers using automated packaging lines

-

-

Storage & Dispatch

-

Stored in cold rooms (4°C) to maintain freshness

-

Ready for distribution to retail or bulk buyers

-

Why Invest in a Curd Production Plant?

-

Growing demand in retail, catering & food industries

-

Low investment, high returns in the dairy sector

-

Can be easily integrated with existing milk processing units

-

Long shelf-life with proper cold chain logistics

TechQu’s End-to-End Curd Plant Solutions Include:

-

Plant Design & Layout Optimization

-

Custom Fabrication of Cheese Equipment

-

Automation & Control Systems

-

In-line Quality Monitoring & CIP Systems

-

Packaging, Storage, and Logistics Setup

-

Compliance with Global Food Safety Standards

Why Choose TechQu?

- 10+ Years of Engineering Experience

- Trusted by Dairy Brands Across India & Overseas

- Turnkey Project Execution from Concept to Commissioning

- Tailored for Small, Medium & Large-Scale Cheese Plants

📞 Get in Touch!

Seeking to start a company for making paneer?

TechQu Engineering is your trusted partner for complete dairy processing solutions.

📞 Call Now: +91 89360 15188

🌐 Visit: www.techqu.co.in

📧 Email: projects@techqu.co.in

👉 Start your dairy journey with TechQu — from design to commissioning!

Explore

Related Products