- Milk Reception Section

- Storage Chilling Raw Material before Process

- Plate Type Pasteurising Section / Cream separation/ Homogenising

- Utility Section( Hot water Generator, Refrigeration System)

- Storage of processed milk in storage tank.

- Packaging Section (Pouch, Bottle Packing)

Mini Dairy Plant

Overview

Mini Dairy Plant

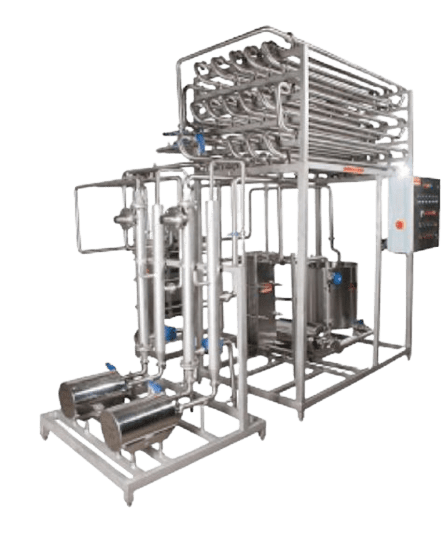

TechQu offers a range of dairy processing equipment, including mini dairy plants. These mini dairy plants are designed to provide a complete solution for small-scale dairy processing, such as for farm-level milk processing, local milk collection centers, and small dairy businesses.

TechQu is able to provide a highest Quality range of Mini Dairy Plant. TechQu offers complete projects for Pasteurized Milk from 500 LPD to 2000 LPD. We can heat milk up to 80° C, holding time 20s, and cooled up to 4° C for final packaging.

Mini dairy plants are small milk factories specially produced for producers who want to produce dairy products with low capacity. It is a small set of equipment in batch or continuous configuration, which could be installed at the dairy farm itself for improving the value addition capacity of a dairy farm and making it commercially more viable and thus sustainable.

The mini dairy plants offered by Techqu Engineering and Projects include a range of equipment, such as milk processing equipment, pasteurizers, homogenizers, separators, milk storage tanks, and filling machines. The equipment is designed to be compact, easy to install, and easy to operate, making it suitable for small-scale dairy processing.

The mini dairy plants are designed to meet the highest quality standards and comply with all relevant regulations and guidelines for dairy processing. They are also designed to be energy-efficient and easy to maintain, which helps to reduce operating costs for the small-scale dairy businesses.

Milk Pasteurization is the process of heating every particle of a product to destroy pathogens. The heat treatment system to be used depends on the properties of the product and the results to be achieved. Here TechQu offers solutions for all the different requirements.

Depending on your product and the desired shelf life, you can choose between various methods of heat treatment, like short time heating – high temperature (STHT), high temperature – short time (HTST), or ultra high temperature process (UHT) by means of indirect or direct heating.

Our expertise in cost effective design, bespoke manufacturing, automation, installation and after sales services has allowed us to be the turnkey solution.

Explore

Related Products